General presentation

The general objective of the PCH team is the development of multifunctional polymeric, composite and hybrid materials with low environmental impact.

Research work focuses on the design of eco-materials, materials made from bio-sourced materials (from plant lignocellulosic materials or marine algae) or recycled materials, and seeks to improve the properties of these materials (mechanical, thermal, reaction to fire, absorption ...) so that they can replace conventional materials often derived from oil and thus reduce the environmental footprint. Work is also being carried out on improving the durability of (eco)-materials and the treatment of plastic and composite waste at the end of its life cycle by various means, including reuse as secondary raw materials, composting and biodegradation. These research actions are positioned in a global bio-economic model involving actors ranging from biomass producers, recycling channels, processors and manufacturers of materials. The fields of application of the studied materials are multiple: building, transport, energy, health, environment, fashion...

Staff

BENEZET Jean-Charles, Lecturer-researcher, HDR

BERGERET Anne, Lecturer-researcher, HDR

BUONOMO Sylvain, Research engineer,

DUMAZERT Loïc, Research engineer,

EVSTRATOV Alexeï, Lecturer-researcher, HDR

FERRY Laurent, Lecturer-researcher, HDR, see the CV

GALLARD Benjamin, Research engineer,

GUIBAL Eric, Lecturer-researcher,

LACOSTE Clement, Lecturer-researcher, see the CV

LE MOIGNE Nicolas, Lecturer-researcher, voir le CV

LIOTIER Pierre-Jacques, Lecturer-researcher,

LONGUET Claire, Lecturer-researcher, HDR

LOPEZ-CUESTA José-Marie, Lecturer-researcher, HDR

OTAZAGHINE Belkacem, Lecturer-researcher, HDR, see the CV

PERRIN Didier, Lecturer-researcher, HDR

RAVEL Romain, Research technician, see the CV

SABOURIN Lionel, Research technician,

SONNIER Rodolphe, Lecturer-researcher, HDR

TAGUET Aurélie, Lecturer-researcher, HDR

VINCENT Thierry, Research and development engineer,

Research topics

This research theme aims to develop materials based on renewable materials using sustainable processes. These activities are mainly broken down into 2 parts.

The first part aims at acquiring a better knowledge of the (micro)structure of biomass and its characteristics for a better control of the performances of materials manufactured from it (biocomposites). The contribution of the PCH team is essentially in the morphological, physicochemical, thermal and mechanical characterization of biosourced substances thanks to original devices allowing the dimensional analysis, the determination of the surface properties, the measurement of the mechanical properties of plant fibres. The effect of the transformation processes of the biomass (grinding, retting among others) are also the object of a particular interest.

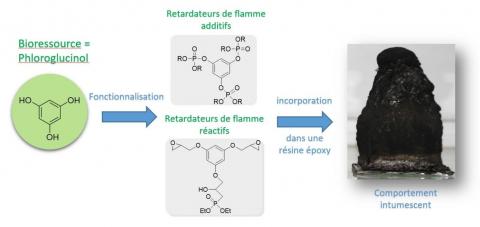

A second component is interested in the multi-scale structuring of biosourced materials in order to control their functional properties. The approach concerns (i) the molecular scale where it is a question of functionalizing the biosourced material in order to confer new properties (fireproofing, hydrophobicity, oleophobicity...), (ii) the microscopic scale since microstructures are crucial in the field of plant fibre composites, foams, biosourced films, or materials developed by additive manufacturing, (iii) the macroscopic scale where the idea is to develop complex multifunctional structures combining different types of biosourced materials (biocomposites, adhesives, foams, films).

The aim of this theme is to understand and control the phenomena at surfaces and interfaces in order to develop materials with functional surfaces or heterophase materials.

In the field of materials with functional surfaces, the work focuses mainly on the shaping and chemical modification of biopolymers for the immobilization of solid and/or liquid charges (fixation of toxic or recoverable metal ions). A range of materials with high percolation power has been developed. Prospects of use of these materials concern the valorisation of metals contained in mining resources or their application as supports for heterogeneous catalysis or antimicrobial activity.

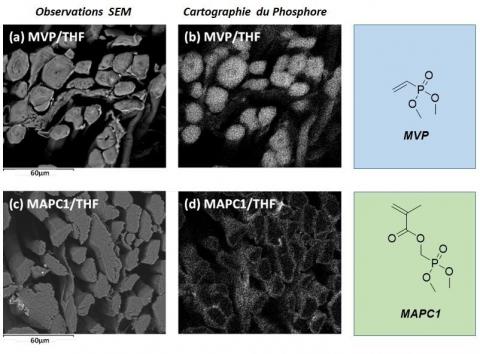

In the field of heterophase materials, studies are focused on the chemical modification of interfaces in fiber composites and nanocomposites with the objective of conferring specific functional properties to the materials (hydrophobicity, fire retardancy, viscosity). Works are also interested in the functionalization of reinforcements assisted by physical treatments (γ-irradiation, e-beam). In particular, radio-grafting processes allow the development of multi-functional materials. The use of nano-objects for the compatibility of heterogeneous materials is also part of the topics investigated.

Finally, a particular effort is made on the characterization and the multi-scale modeling of interfaces, in particular thanks to various experimental tools of the MOCABIO platform.

This axis is interested in the life cycle of polymeric and composite materials and more particularly in the evolution of functional properties during use under severe and complex conditions and the design of new functionalities for a second life cycle.

In the field of durability and aging of polymeric and composite materials, the team's expertise lies in the multi-scale approach of the phenomena (micro, meso, macro relationships) and in the analysis of multi-physical couplings (hygro-thermo mechanical coupling in particular). The work focuses on the study of degradation and damage mechanisms and their kinetics. Original methods, based on the coupled application of stimuli (humidity and mechanical stress for example) have also been developed to assess the durability of (bio)composites.

Regarding the end of life and recycling of polymeric materials, studies focus on the characterization of deposits, sorting methods, but also the control of comminution processes in order to prepare secondary raw materials with controlled properties. Concerning the valorization of products at the end of their life, different ways are explored: mechanical recycling, chemical recycling and important perspectives concern enzymatic recycling which should allow the programmed degradation of materials at the end of their life. It should be noted that the team is particularly interested in the end of life of bio-based materials and the recovery of materials with high added value such as carbon fibers.

The aim of this research area is to understand and improve the fire behavior of polymeric materials through the development of flame retardant systems and the understanding of combustion phenomena in relation to the structure of materials.

The work of the PCH team focuses on the development of low environmental impact flame retardants based on functionalized inorganic particles and nanoparticles but also based on biosourced materials possibly modified by active groups (phosphorus in particular). The study of the reaction concerns very varied polymers and more particularly biopolymers and biocomposites. The recent themes concern in particular the elaboration of fireproof polymers obtained by additive manufacturing, and the development of fireproof coatings for structural composites.

The research work of the team also concerns the influence of flame retardancy on the other performances of materials, in particular their resistance to aging, their recyclability or their sanitary properties in service or during a fire.

It should be noted that the work carried out is interested in the reaction to fire of materials at different scales and methodologies are developed to determine analytical laws linking these scales. A field of application illustrates this approach perfectly, it is that of the cable industry for which several studies are in progress. Finally, more and more works simultaneously take into account the reaction to fire and the resistance to fire, which requires the studying of the thermal/mechanical couplings.

International collaborations

At the European level, PCH is deeply involved in two networks: ENMAT (European Network on MATerials), a general network on materials, and EPNOE (European Polysaccharides Network of Excellence), a network focused on agroresources and biopolymers that brings together 40 major European universities and for which IMT mines Alès is the headquarters. The team also has direct collaborations with a number of European institutions such as the University of Bolton (Great Britain), the University of Trento (Italy), MateriaNova (Belgium), the LIST (Luxembourg), and the EMPA (Switzerland).

Internationally, PCH has developed a network of academic partnerships with emerging countries, notably through bilateral programs (PHC and CAPES-COFECUB). In this context, the main partners are the University of Bejaia (Algeria), the University of Rio Grande do Sul in Porto Alegre (Brazil), the University of Monastir (Tunisia), and the Nuclear Materials Authority in Cairo (Egypt).

PCH has many partnerships with industrial companies, e.g. Acome, Armor, Cellmark, Corning, Eranova, FRD, Gerflor, IXBlue, Lafarge Holcim, Naval group, Pellenc, Saint-Gobain, Silvadec, Segula Technologies