Presentation - Missions

A mechatronic system is able to perceive its environment, to process information, to communicate, to act in and on its environment, and presents a complete level of integration from the functional, physical and disciplinary point of view.

The mechatronics platform is run by a permanent team of seven people, including three engineers, three technicians and one administrative assistant. It is attached to the PRISM technological teaching department of the CERIS teaching and research center.

The missions of the mechatronics platform

- To support quality teaching in the disciplines of mechatronics (general engineering training and mechatronics specialization by apprenticeship). To supervise students' work (pedagogical and personal work) in this field in liaison with client companies.

- Supporting the creators of the IMT Mines Alès incubator

- Conducting research and development activities for companies and research teams.

Our offer of skills and know-how

The originality of the PFM is its interdisciplinary and collaborative approach to design problem solving and its ability to cover the entire product development cycle, from the needs analysis to the validation of an operational prototype.

The skills present at the PFM are :

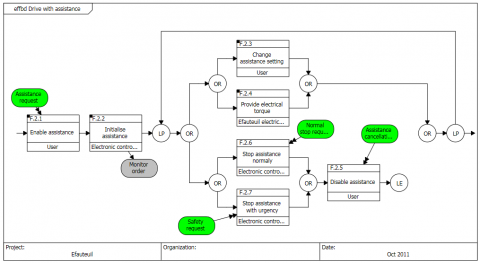

From the needs expressed by the stakeholders interacting with the product throughout its life cycle, functional and organic architectures are defined as well as verification and validation actions. This system engineering phase provides the specifications for the business components which, once completed, are integrated to form the final product.

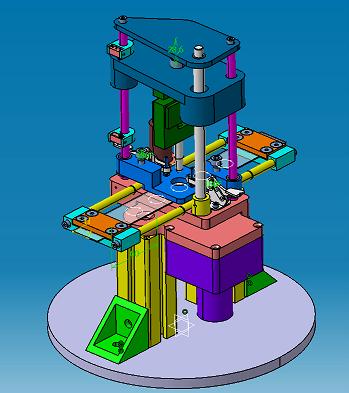

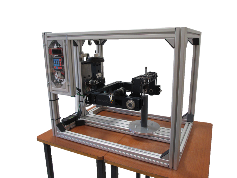

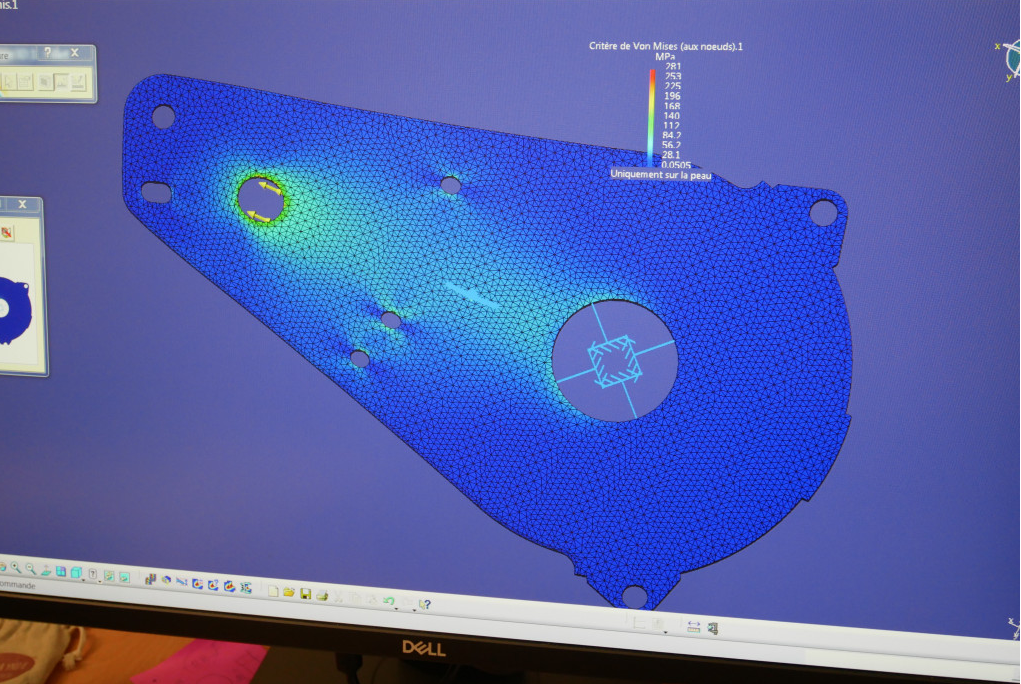

The mechanical design on CAD takes into account the requirements of the CoP but also the manufacturing constraints (machining, molding, 3D printing) and allows a 3D visualization to facilitate the analysis. After structural calculations and simulation, the data for manufacturing are generated (CAM).

PFM has the know-how in milling/turning/waterjet cutting/3D printing/welding to realize functional prototypes for its customers. Various dimensional control tools including a 3D measuring machine are used to check and validate the parts and assemblies made.

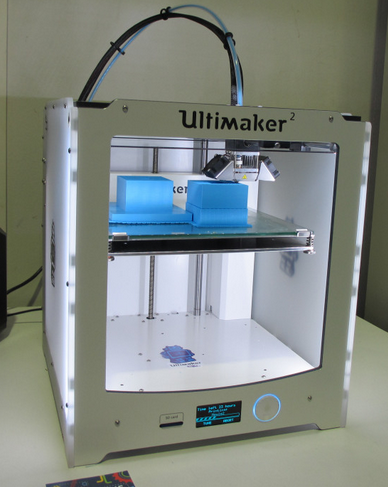

Whether to validate the principles of solutions around a 3D model of the product or to produce certain complex parts, manufacturing by adding material (FDM or SLS technology) has now been imposed. Reworking on machine tools is possible in hybrid design.

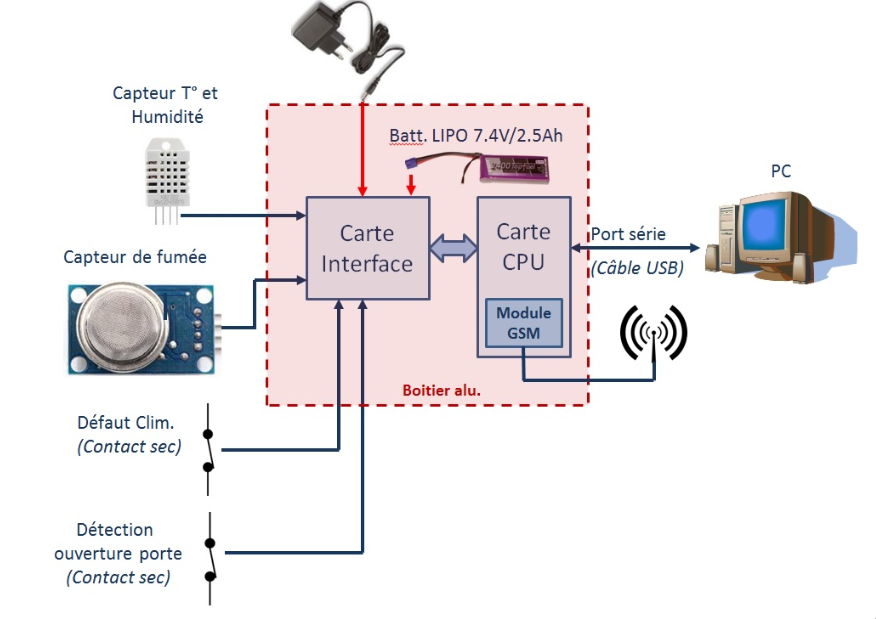

A mechatronic system perceives its environment (through sensors), processes information, communicates and reacts on and in its environment (through actuators). These capabilities are largely based on microelectronic systems technologies which have an increasing role in 'intelligent' systems.

Cyber-physics connects objects, from the simplest to the most complex, to computer applications deported to the 'cloud' in order to offer new services. These technologies implement communicating electronic systems with a high level of integration and low energy consumption.

Our main achievements

We work in various fields of application illustrated below with our clients, whether they are business creators within the IMT Mines Ales incubator, or industrial partners:

For the past twenty years, projects have been carried out to meet the needs of people with reduced mobility with adaptations of existing equipment, specific developments or the design of innovative products. Our latest achievements in the health field concern technical aids for health personnel (surgical nail, test benches, ear surgery simulator, ergometer, etc.).

IMT Mines Alès via the PFM is the leader of the MUSCLUS EXCENTRICUS project, "Ergometer at the dialysis patient's bed" financed by the Occitanie region within the framework of the Research and Society call for projects in partnership with the UMR DMeM (UM) and Aider Santé.

To limit carbon emissions into the environment, electric vehicles are becoming very popular. With the IUT of Nîmes, we have developed powerful brushless motors operating at low voltage (<100V). They have enabled us to develop innovative electric vehicles: Kart, PGO e-Hemera, the first prototype of electric winegrower tractor (for the FGVI association of winegrowers of the gard FGVI), watercraft, ...

We have realized applications in robotics (for the company Fadilec: demonstrator of a robot to control the radioactivity of a waste drum) and in mobile robotics (development of a robot to inspect a contaminated site for the CEA).

More and more technical objects are connected to the cloud to provide more and more information. We have realized a remote control system for isolated electrical cabinets in the countryside (for Cannon) and an automated stirring device (for S. Delafont).

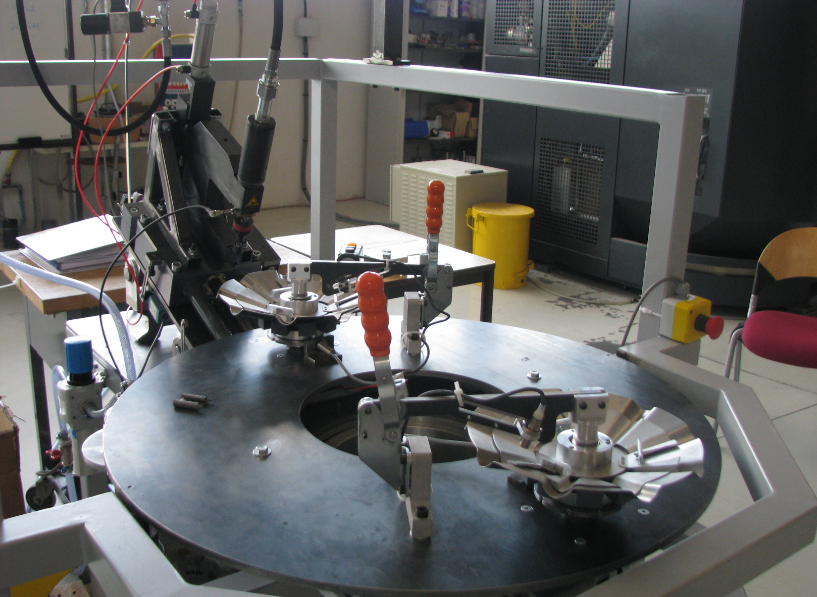

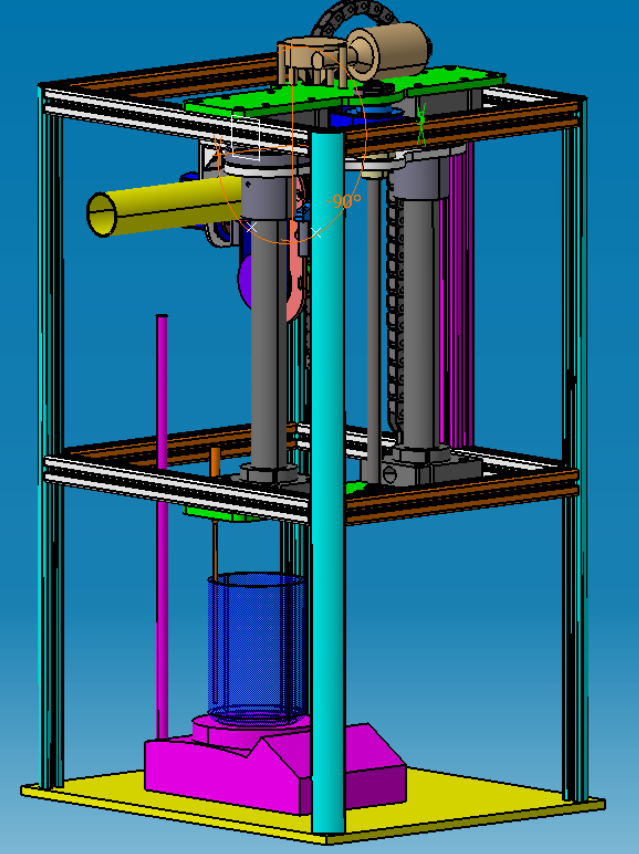

We have studied and realized various special machines such as a mattress testing machine (for the Asklé Santé company), a clinching assembly machine (for the Sobat company).

We develop for our research laboratories devices such as: fraction collector, soaking robot, test benches, dental implant wear test machine...

Students' achievements

Within the framework of general engineering training and apprenticeship training in Mechatronics, our students are put in the position of developing innovative products on subjects originating from our industrial partners, our laboratories or the students themselves. The students find on the PFM the necessary advice and supervision for the success of these projects.

The Cévennes Car Club is a student association whose goal is to design and build eco-innovative vehicles by participating in events and competitions around motorsports. The students of IMT Mines d'Alès, the IUT of Nîmes and the CFA of Alès join forces with numerous industrial partners to contribute to the development of tomorrow's eco-mobility.

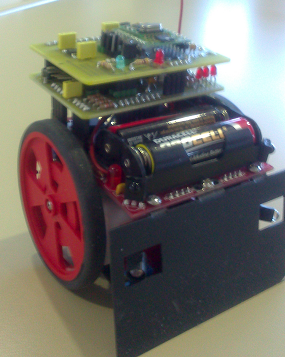

During the three-year pedagogical exercise, the Mechatronic engineers apprentices have to develop a complex mechatronic system such as an investigation robot for the CEA.

The testing machine for trapezo-metacarpal medical prostheses is an example of pedagogical work carried out for the OSD company, in the last year of engineering training in mechatronics option.

Mobile robotics allows to introduce students in a playful way to many disciplines: microelectronics, computer science, embedded systems ... The possibilities of exercises are as numerous as the ideas coming out of the imagination of our students.

Our equipment

The PFM has professional equipment to carry out for its customers the various phases of development of a product from the idea to the functional prototype. It offers in particular to the projects resulting from the Fablabs, the possibility of an operational realization for validation in view of a future industrialization.

| Development tools | Usage |

|---|---|

|

3Dexperience / Dassault |

CAD, System Engineering (RFLP), PLM, Simulation |

| Symdesigner | Dynamic analysis of solids |

| ANSYS | Finite element calculation |

| Eagle | Electronic CAD |

| Microprocessor programming | Microchip, Arduino, Rasberry Pi |

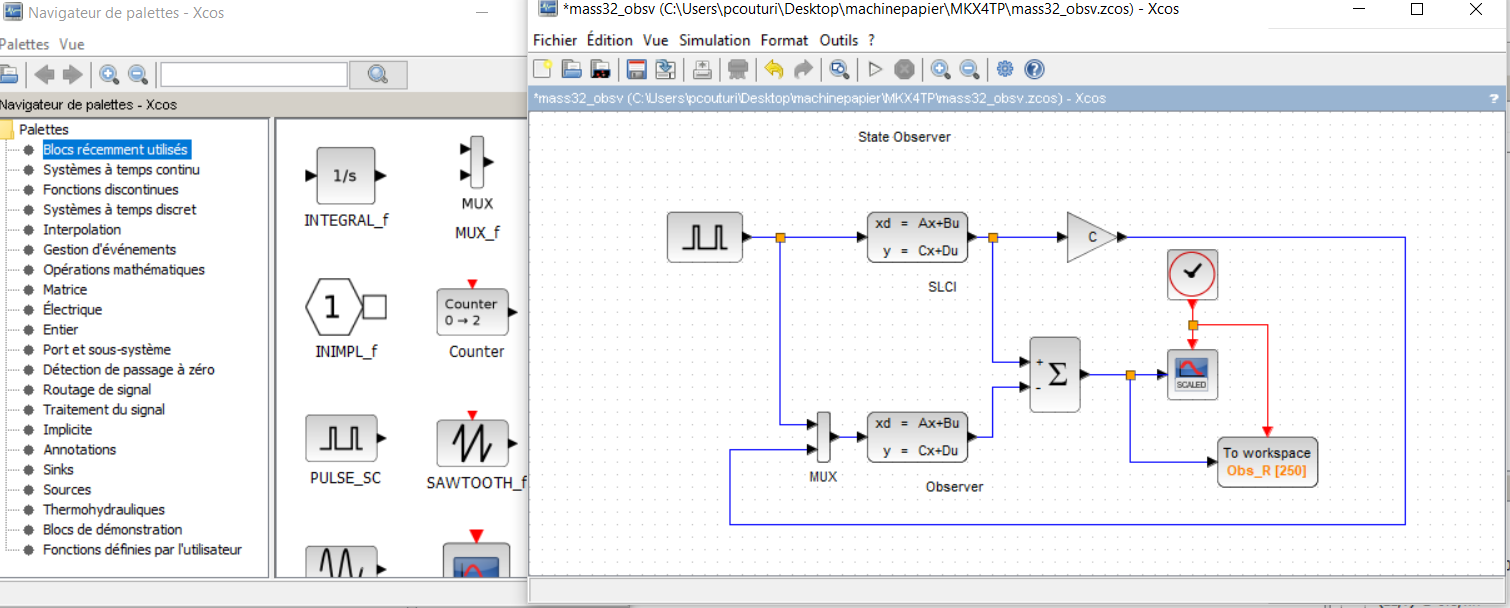

| Matlab/Simulink | Signal processing , Control command |

| Amesym | Multiphysics simulation |

| Equipement | Caractéristiques | |

|---|---|---|

|

|

|

|

|

2.5 axis lathe

|

|

|

|

|

|

|

| Additive construction |

|

|

|

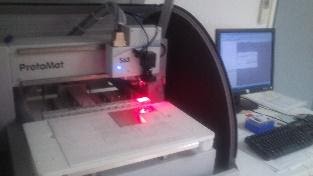

Plate milling machine |

|

|

|

Welding / Cutting |

|

|

| Printed circuit workshop |

|

|

| Equipement | Caractéristiques / Usage | |

|---|---|---|

|

Three-dimensional measuring machine |

|

|

| Labview, Matlab/Simulink |

|

|

| Measuring devices |

|

|

|

|

|

|